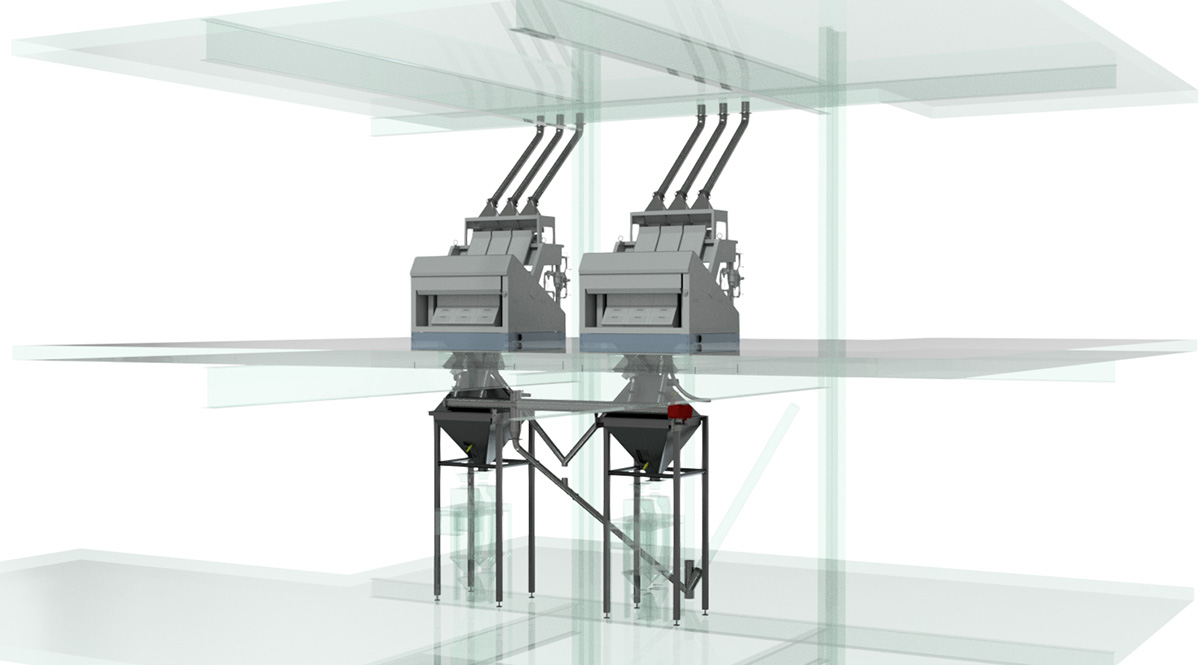

Design Colour Sorter intallation upgrade in packaging plant

| Details: |

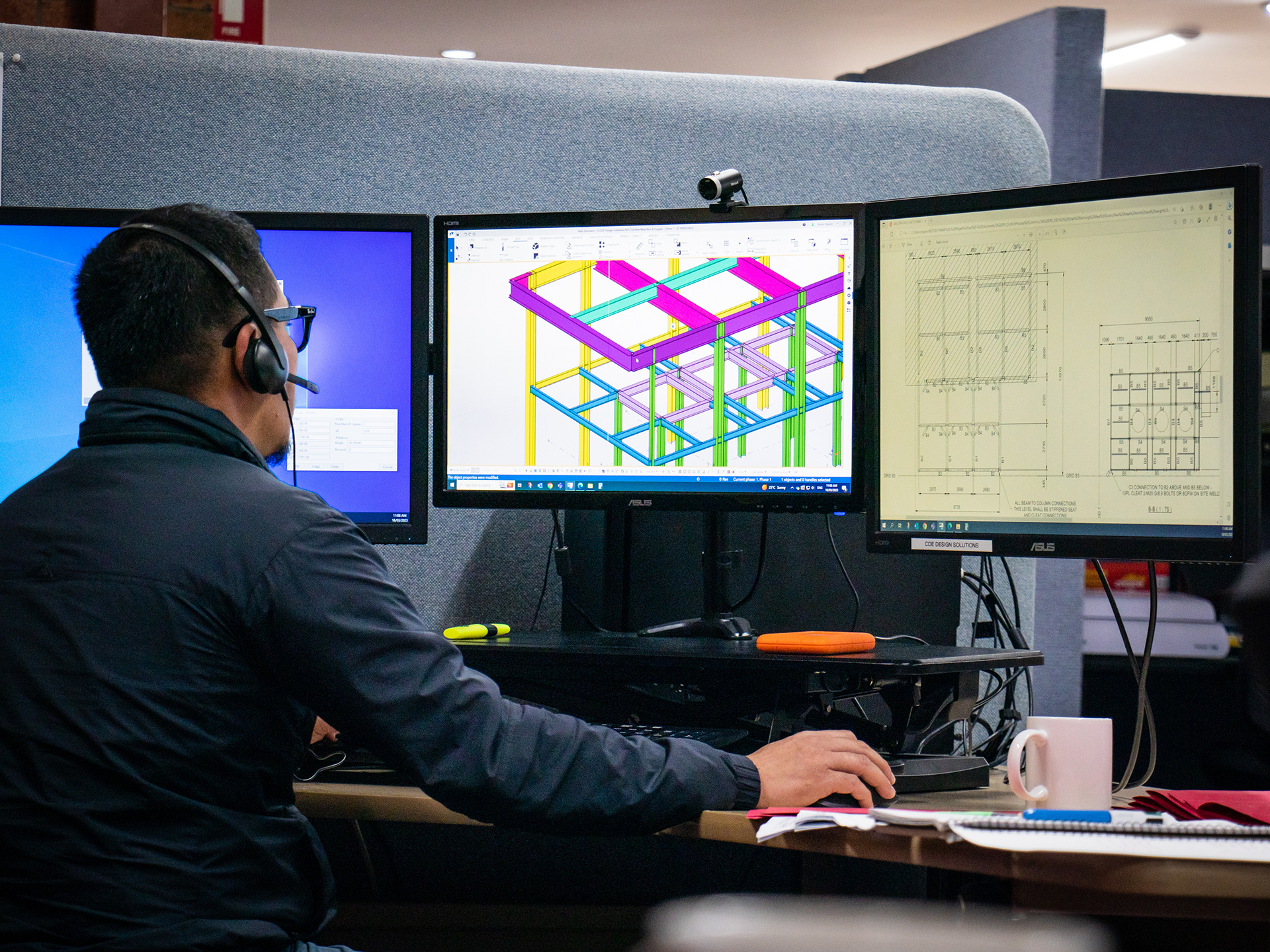

In this upgrade to their rice colour sorting process line upgrade, the clients main challenge was a very small downtime window in order to replace old equipment with new equipment, including auxilliary components that interface with the equipment including air ducting. It was essential to minimise production line downtime and the entire upgrade was required to fit into a predetermined, tight factory wide maintenance period. All machinery and auxilliary equipment needed to be replaced seemlessly with no time delay during installation. Pre planning was critical and had to be perfect. CDE designed the installation in a way to ensure no extra downtime and mitigated all potential issues whilst having 100% confidence that all new equipment would fit. In addition, a plan to mitigate anything that may have gone wrong was required in advance. Part of the job was to consider the manufacturers and the installers capabilities and to ensure the design accommodated the capabilities and preferences of the local installation team. |

|---|---|

| Industry: | Food Processing |

| Size: | $200k to $1m |

| Developmental stage: | Brown Field |

| Service: | 3D Modelling, Drafting, 3D Scanning |